CAPABILITIES

RobotIc WeldIng Cells

(5 lines – ABB & Yaskawa)

Five robotic welding lines deliver consistent weld quality, optimized heat control, and high-cycle productivity. This fully automated setup minimizes human variability and ensures structurally reliable joints for complex assemblies.

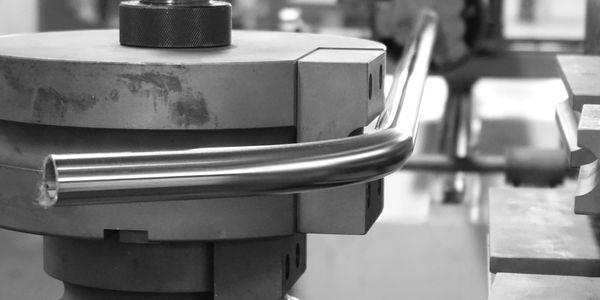

CNC Tube and ProfIle BendIng

(2 lines up to 70 mm)

Our CNC bending systems enable repeatable, high-accuracy forming for tubes and profiles up to 70 mm. Automated processing ensures tight tolerances, stable geometry, and scalable batch production for demanding applications.

SHEET BENDING & PRESSES

Our sheet-forming capability covers precision bending and press operations for a wide range of material thicknesses. Automated press brakes and forming presses ensure repeatable angles, stable dimensions, and efficient cycle times for both prototypes and serial production.

Tube/ProfIle & SHEET Laser CuttIng

(Tube Laser 3 kW) & (5-Axis Sheet Laser (3×2 meter))

Our laser systems provide precision cutting for tubes, profiles, and 3D geometries. The 5-axis platform enables complex contours and multi-angle cuts, supporting prototyping, small batches, and large-scale industrial production.

ElectrostatIc Powder CoatIng

The powder-coating line ensures durable, corrosion-resistant surface finishes with uniform coating quality. Automated application methods support both aesthetic and functional requirements across diverse product groups.

.jpg/:/rs=w:600,h:300,cg:true,m/cr=w:600,h:300)

DesIgn & R&D EngIneerIng

(Tooling, Fixtures, Simulation)

Our in-house engineering team designs tooling, welding fixtures, and custom production equipment. Digital simulation capabilities allow us to optimize part geometry, validate feasibility, and accelerate transfer to serial manufacturing.

© 2025 MWK Metall GmbH - ALL RIGHTS RESERVED

Bu web sitesinde çerez kullanılır.

Web sitesi trafiğini analiz etmek ve web sitesi deneyiminizi optimize etmek amacıyla çerezler kullanıyoruz. Çerez kullanımımızı kabul ettiğinizde, verileriniz tüm diğer kullanıcı verileriyle birlikte derlenir.